In the intricate realm of Very Large Scale Integration (VLSI), two crucial processes, Design for Testability (DFT) and Functional Verification, stand as pillars ensuring the robustness and reliability of semiconductor designs. Let’s delve into the significance of each and how they contribute to the seamless operation of VLSI circuits.

Design for Testability (DFT): Constructing a Solid Foundation

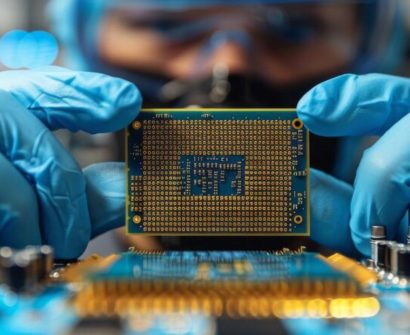

Design for Testability is not merely a phase in VLSI design but a philosophy that architects follow from the inception of a project. DFT is all about ensuring that a chip can be effectively and thoroughly tested once it’s manufactured. This proactive approach involves the integration of specific features and techniques during the design phase to simplify the testing process.

Key Aspects of DFT:

- Scan Chains:

- DFT incorporates scan chains, allowing for efficient testing by serially shifting in and out test data.

- Built-in Self-Test (BIST):

- BIST modules within the chip facilitate autonomous testing, reducing dependence on external test equipment.

- Fault Models:

- DFT addresses various fault models, ensuring that potential issues like stuck-at faults or bridging faults are detected during testing.

- Test Access Mechanisms (TAM):

- Efficient TAM design ensures seamless access to various components for testing purposes.

Functional Verification: Ensuring Operational Integrity

While DFT focuses on testability, Functional Verification is concerned with validating that the chip performs its intended functions correctly. It’s the process of confirming that the design adheres to specifications and behaves as expected under normal operating conditions.

Key Aspects of Functional Verification:

- Simulation:

- Simulation tools are employed to mimic real-world scenarios, ensuring the chip’s behavior aligns with the design intent.

- Formal Verification:

- Mathematical techniques are used to prove the correctness of a design, providing a high level of confidence.

- Emulation and Prototyping:

- Larger and more complex designs benefit from emulation and prototyping to validate performance in a real-world environment.

- Assertion-Based Verification:

- Assertions are statements embedded in the design to check specific conditions, enhancing the reliability of verification.

The Symbiosis: Integrating DFT with Functional Verification

The dynamic nature of VLSI design demands a synergistic approach, where DFT and Functional Verification complement each other. Design for Testability paves the way for a comprehensive testing infrastructure, and Functional Verification ensures that the chip not only passes the tests but operates correctly in real-world scenarios.

In Conclusion: Balancing Act for Optimal Results

In the VLSI landscape, Design for Testability and Functional Verification are not competing forces but collaborative elements ensuring the success of semiconductor designs. A harmonious integration of these processes results in chips that not only meet the highest quality standards but also stand resilient against the challenges posed by the ever-evolving technological landscape. As we continue to push the boundaries of VLSI, the careful balance between DFT and Functional Verification remains the linchpin for success in semiconductor design.

To know more about VLSI Course , SuccessBridge VLSI training institute. You can begin your VLSI career by enrolling in the placement-assisted live courses available at SuccessBridge We offer various VLSI online courses. We offer VLSI Physical Design course, Design Verification course, DFT Training,Chip design course many more. Explore VLSI Courses From The Leaders In VLSI Training

Also Read: A Walkthrough VLSI Physical Design Engineer Salary In India.