In the ever-evolving landscape of Very Large Scale Integration (VLSI), where the quest for smaller, faster, and more efficient chips is unending, engineers are constantly exploring innovative techniques to push the boundaries of chip design and fabrication. One such technique that has gained significant traction in recent years is double patterning. This sophisticated approach to lithography has become indispensable in achieving the precision required for cutting-edge semiconductor manufacturing. In this blog post, we delve into the intricacies of double patterning in VLSI, exploring its principles, applications, and implications for chip fabrication.

Understanding Double Patterning:

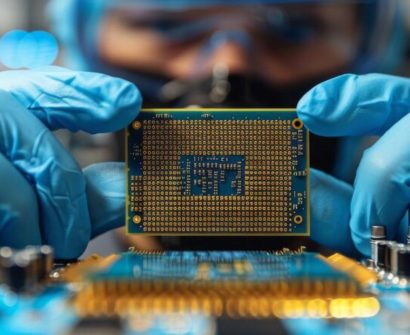

At its core, double patterning is a lithography technique used to overcome the limitations of traditional single patterning in achieving finer feature sizes. In single patterning, a single exposure of light onto the photoresist layer is used to transfer the pattern from the mask onto the semiconductor substrate. However, as feature sizes continue to shrink, the diffraction limit of light becomes a significant impediment, leading to reduced resolution and increased pattern distortion.

Double patterning mitigates these challenges by dividing the original pattern into two separate exposures, each with its distinct set of features. By effectively splitting the pattern into two complementary halves, the resolution limit of each exposure is relaxed, enabling the fabrication of finer geometries than would be possible with single patterning alone. The two exposures are typically achieved using different colors of light or polarizations, allowing for precise alignment and overlay.

Applications of Double Patterning:

Double patterning finds widespread application in various critical areas of VLSI design and fabrication:

- Advanced Logic and Memory Devices: In the race towards smaller transistor dimensions and higher packing densities, double patterning plays a pivotal role in enabling the fabrication of intricate logic gates and memory cells with nanoscale precision.

- High-Performance Computing (HPC): Double patterning is indispensable in the development of next-generation processors and accelerators for HPC applications, where the demand for increased computational power and energy efficiency continues to drive chip miniaturization.

- System-on-Chip (SoC) Integration: As SoCs become more complex, incorporating diverse functionalities onto a single chip, double patterning facilitates the integration of multiple layers of transistors, interconnects, and other components, enabling seamless system integration and optimal performance.

Implications and Challenges:

While double patterning offers significant advantages in enhancing chip fabrication precision, it also presents several challenges and implications for VLSI engineers:

- Complexity: Implementing double patterning adds complexity to the chip design and manufacturing process, requiring careful planning and optimization to ensure proper alignment, overlay, and pattern fidelity.

- Cost: The additional steps involved in double patterning, including multiple exposures, etching processes, and alignment procedures, contribute to increased manufacturing costs, impacting overall chip production expenses.

- Design Constraints: Double patterning imposes certain design constraints, such as minimum pitch requirements and restrictions on pattern density, which may influence the layout and architecture of VLSI circuits.

Conclusion:

In the realm of VLSI design and fabrication, where the pursuit of higher performance, lower power consumption, and greater functionality is relentless, double patterning stands out as a fundamental enabler of semiconductor innovation. By harnessing the principles of complementary patterning and precision lithography, engineers can push the boundaries of chip miniaturization and complexity, paving the way for the next generation of electronic devices and systems.

Also Read: A Walkthrough VLSI Physical Design Engineer Salary In India.

To know more about VLSI Course , SuccessBridge VLSI training institute. You can begin your VLSI career by enrolling in the placement-assisted live courses available at SuccessBridge We offer various VLSI online courses. We offer VLSI Physical Design course, Design Verification course, DFT Training,Chip design course many more. Explore VLSI Courses From The Leaders In VLSI Training

As semiconductor technologies continue to evolve, and the demand for smaller, more powerful chips intensifies, the role of double patterning in VLSI will only become more pronounced. By understanding its principles, applications, and challenges, engineers can leverage this sophisticated technique to drive advancements in chip design, manufacturing, and ultimately, the realization of cutting-edge electronic devices that shape our modern world.