DFT (Design for Testability) in VLSI: Importance, Techniques, and Best Practices

Introduction

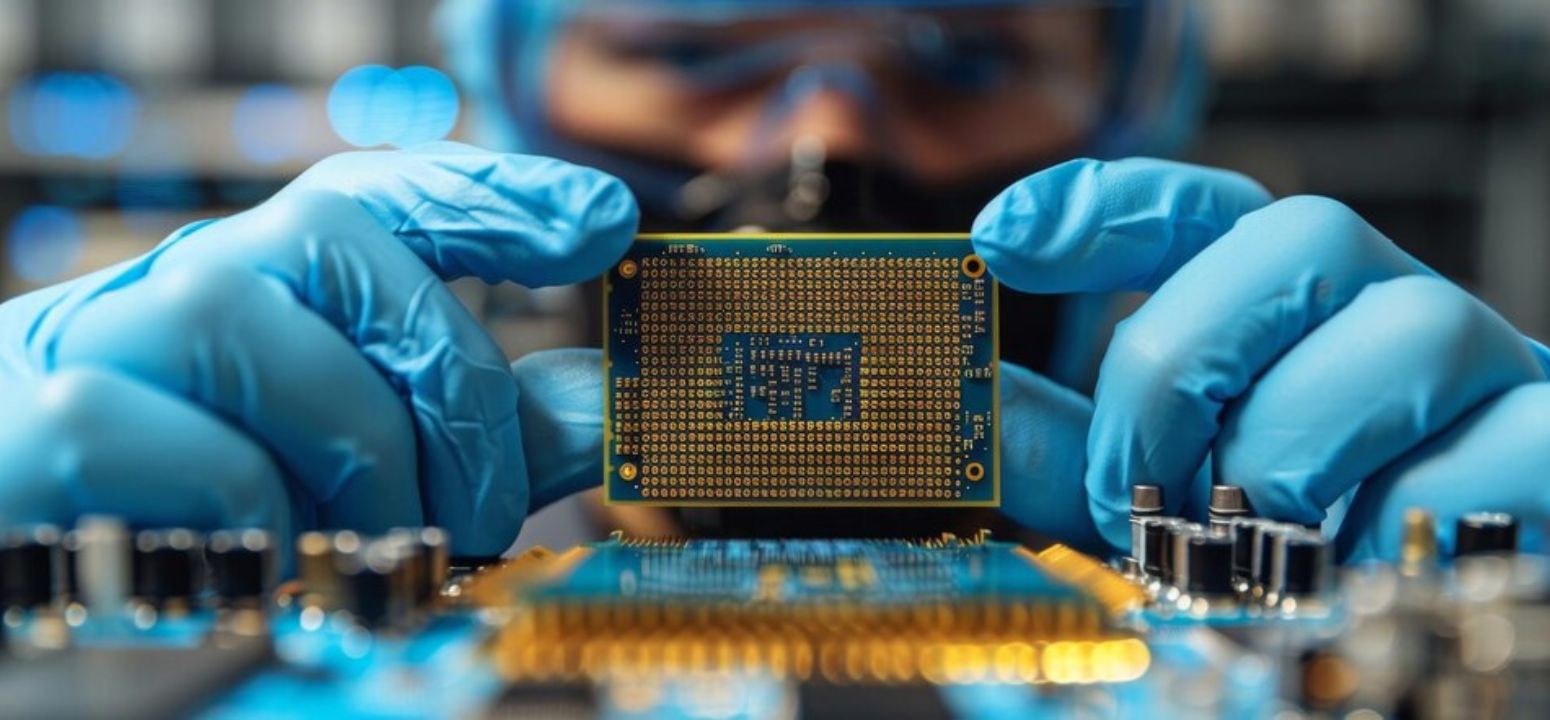

Design for Testability (DFT) is an essential aspect of Very Large Scale Integration (VLSI) design that ensures semiconductor devices can be efficiently and accurately tested before deployment. As chip designs become more complex, DFT techniques help detect and diagnose manufacturing defects, improving yield and reliability. This blog explores the importance of DFT in VLSI, key testing techniques, and best practices for effective implementation.

Importance of DFT in VLSI

DFT plays a critical role in the semiconductor industry for several reasons:

- Fault Detection: Helps identify defects in integrated circuits (ICs) at an early stage, reducing time-to-market.

- Manufacturing Yield Improvement: Enhances chip yield by identifying and rectifying production faults.

- Cost Efficiency: Reduces test time and minimizes costly field failures.

- Reliability: Ensures long-term performance and dependability of semiconductor devices.

Key DFT Techniques

To facilitate testing, several techniques are used in DFT methodologies. Some of the most widely adopted ones include:

1. Scan Chain Insertion

Scan chains simplify testing by allowing the internal state of flip-flops to be controlled and observed. This technique is crucial for Automatic Test Pattern Generation (ATPG) and significantly improves fault coverage.

2. Boundary Scan (IEEE 1149.1 JTAG)

Used for board-level testing, boundary scan technology enables testing of interconnections between ICs without requiring physical probe access. It is particularly useful in complex PCBs where traditional testing methods are inadequate.

3. Built-In Self-Test (BIST)

BIST is an embedded testing solution that enables a chip to test itself without external test equipment. It is widely used in memory testing, logic testing, and analog circuit testing.

4. Memory BIST (MBIST)

A specialized form of BIST, MBIST is used to test embedded memory blocks, such as SRAM, DRAM, and Flash memory. It ensures memory integrity and functionality.

5. Logic BIST (LBIST)

LBIST provides on-chip logic testing capabilities, allowing functional verification without external intervention. It enhances reliability in safety-critical applications like automotive and aerospace electronics.

6. Delay Test and Transition Fault Testing

These methods detect timing-related faults in high-speed circuits, ensuring that chips operate correctly at the intended clock speeds.

Best Practices for Implementing DFT

To maximize the benefits of DFT, VLSI designers should adhere to these best practices:

- Integrate DFT Early in the Design Flow: Incorporate testability features at the RTL level rather than as a post-layout fix.

- Optimize Scan Chain Insertion: Ensure scan chains are logically structured to minimize test time and area overhead.

- Use Hierarchical DFT Approaches: Implement DFT at module-level first, then integrate into the top-level design.

- Perform Fault Simulation and Coverage Analysis: Verify DFT effectiveness using fault grading metrics before tape-out.

- Leverage Automated DFT Tools: Use industry-standard tools such as Synopsys DFT Compiler, Mentor Tessent, and Cadence Modus for seamless DFT implementation.

- Ensure Compatibility with ATE (Automated Test Equipment): Validate that the test patterns generated are compatible with production test setups.

Conclusion

Design for Testability is indispensable in modern VLSI design, ensuring efficient defect detection, improved yields, and cost-effective manufacturing. By integrating DFT techniques early in the design process and following best practices, semiconductor companies can produce high-quality, reliable ICs. As technology evolves, advancements in AI-driven testing and machine learning-based fault diagnosis will further enhance the efficiency of DFT methodologies.

Are you looking to enhance your expertise in DFT and VLSI testing? Explore our Design for Testability Online Course at SuccessBridge and elevate your VLSI career today!