Scaling in Very Large Scale Integration (VLSI) technology has been a cornerstone of the semiconductor industry, enabling faster, smaller, and more power-efficient devices. However, as technology advances into the nanometer regime, several limitations have emerged, challenging the continuation of Moore’s Law. This blog explores the key limitations of scaling in VLSI, considering aspects such as physics, design, and manufacturing.

1. Physical Limitations

As device dimensions shrink, fundamental physical constraints come into play:

- Quantum Effects: At nanometer scales, quantum mechanical phenomena, such as tunneling, become significant. For instance, electrons can tunnel through thin gate oxides, leading to leakage currents.

- Short-Channel Effects (SCE): Reduced channel lengths in transistors cause issues like threshold voltage roll-off and drain-induced barrier lowering (DIBL), which degrade device performance.

- Thermal Issues: Smaller devices generate more heat due to higher power density. Managing heat dissipation becomes increasingly challenging.

2. Material Limitations

Traditional silicon-based technology faces material challenges:

- Silicon Limits: Silicon has reached its limits in terms of electron mobility and thermal conductivity. Advanced materials like silicon-germanium (SiGe) and III-V compounds are being explored but come with integration challenges.

- Interconnect Scaling: As transistors shrink, interconnects also scale down, leading to increased resistance and capacitance. This results in higher RC delays and impacts signal integrity.

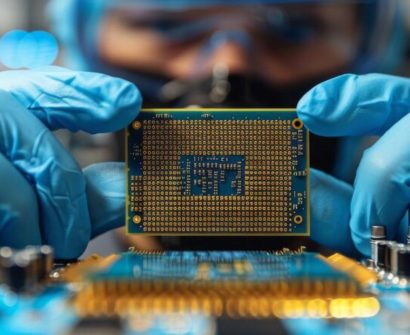

3. Manufacturing Challenges

Scaling places immense pressure on manufacturing processes:

- Lithography Limitations: Current photolithography techniques struggle to achieve accurate patterning at nanometer scales. Extreme ultraviolet (EUV) lithography, while promising, is costly and complex.

- Process Variations: Variability in fabrication processes increases at smaller scales, leading to inconsistencies in device performance.

4. Economic Constraints

The cost of scaling has skyrocketed:

- Rising R&D Costs: Developing new technologies for scaling demands significant investment in research and development.

- Manufacturing Costs: Advanced fabrication facilities require substantial capital, making scaling economically unviable for smaller companies.

5. Design Complexity

Designing at smaller nodes introduces significant complexity:

- Power Integrity: Leakage currents and dynamic power consumption complicate power management.

- Signal Integrity: Crosstalk and noise become critical issues, requiring advanced design techniques to mitigate their effects.

- EDA Tool Limitations: Existing electronic design automation (EDA) tools face challenges in handling the intricacies of nanometer-scale designs.

6. Reliability Issues

Device reliability degrades with scaling:

- Electromigration: Narrower interconnects are more prone to electromigration, affecting device lifespan.

- Bias Temperature Instability (BTI): Smaller devices are more susceptible to BTI, impacting long-term reliability.

7. Power Constraints

While scaling aims to reduce power consumption, certain issues persist:

- Static Power: Leakage currents contribute significantly to static power dissipation.

- Dynamic Power: Higher switching speeds increase dynamic power requirements, posing a paradox for power-efficient design.

Mitigating Limitations of Scaling in VLSI

To overcome these challenges, the industry is exploring alternatives:

- 3D Integration: Stacking multiple layers of devices to improve performance and reduce footprint.

- Beyond CMOS: Investigating new technologies like quantum computing, spintronics, and carbon nanotubes.

- Advanced Materials: Using graphene, molybdenum disulfide (MoS2), and other emerging materials for better performance.

- Design Innovations: Employing techniques like FinFETs, gate-all-around transistors, and advanced EDA tools.

Conclusion

While scaling in VLSI has driven remarkable advancements, its limitations highlight the need for innovation beyond traditional approaches. By addressing these challenges through material science, manufacturing innovations, and design strategies, the semiconductor industry can continue to achieve breakthroughs in technology. The future lies in balancing the trade-offs of scaling with innovative solutions to maintain progress in VLSI technology.

Also Read : fpga architecture in vlsi

To know more about VLSI Course , SuccessBridge VLSI training institute. You can begin your VLSI career by enrolling in the placement-assisted live courses available at SuccessBridge We offer various VLSI online courses. We offer VLSI Physical Design course, Design Verification course, DFT Training , Chip design course many more. Explore Courses From The Leaders In VLSI Training

FAQs

1. What is scaling in VLSI? Scaling refers to the reduction of device dimensions to improve performance, reduce power consumption, and increase transistor density.

2. Why is scaling important in VLSI? Scaling enables the production of smaller, faster, and more power-efficient devices, aligning with Moore’s Law.

3. What are the alternatives to traditional scaling? Alternatives include 3D integration, advanced materials, and new device architectures like FinFETs and gate-all-around transistors.