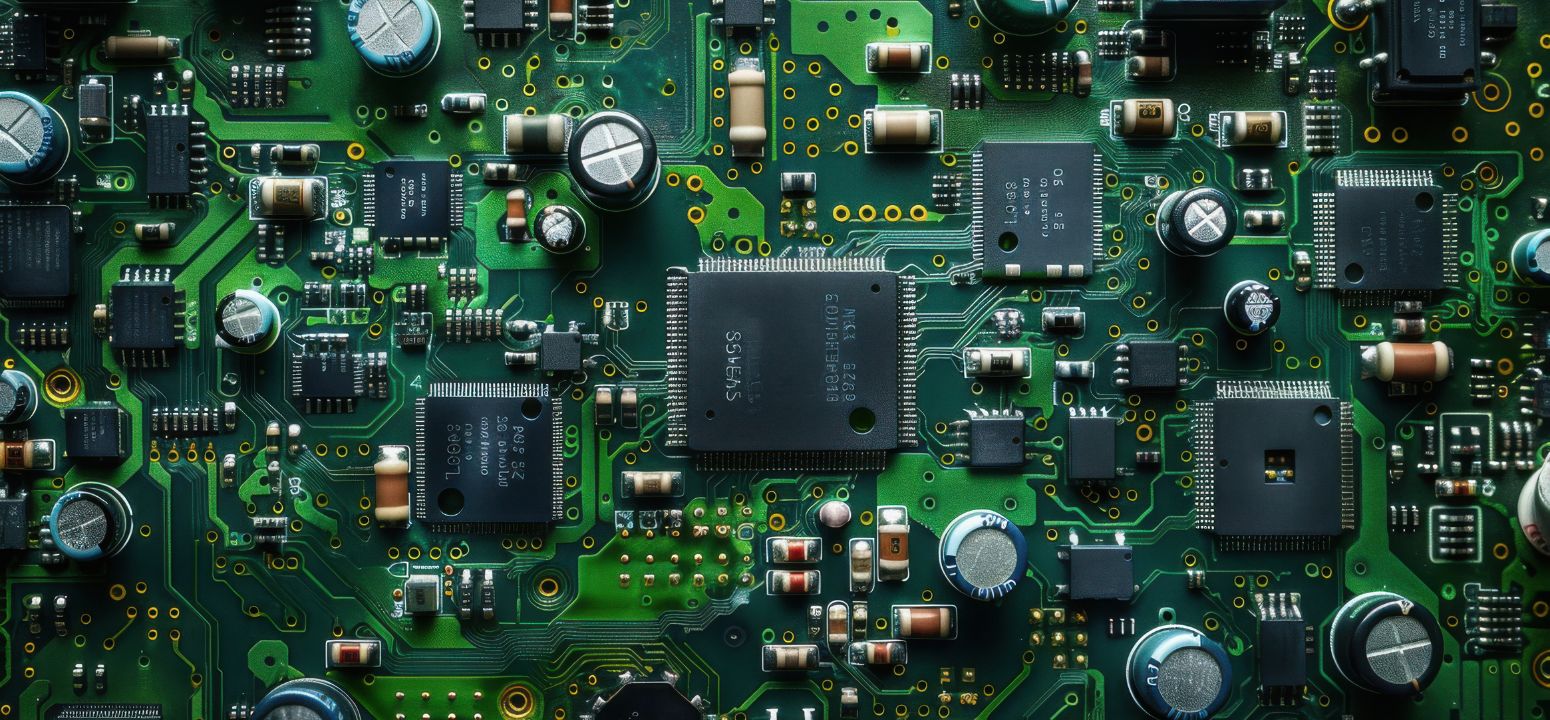

In the world of electronics, high-speed PCB routing is a critical design factor, especially as modern devices continue to push the limits of processing power and functionality. As frequencies and signal speeds increase, routing for high-speed designs becomes more complex, with signal integrity and noise reduction being top priorities. Let’s explore the challenges of high-speed PCB designs and the best routing practices that can help ensure reliable performance.

Challenges in High-Speed PCB Routing

Designing a high-speed PCB brings several unique challenges, including:

- Signal Integrity Issues: At higher frequencies, signals become more susceptible to degradation. Factors like trace impedance, crosstalk, and reflection can cause signal integrity issues that lead to malfunction.

- Electromagnetic Interference (EMI): As signal speeds increase, so does the risk of EMI, which can disrupt the performance of nearby components and even the PCB itself.

- Timing Skew: Ensuring that signals arrive at their destinations simultaneously is critical in high-speed designs. Misalignment in signal timing, known as skew, can result in errors.

- Heat Dissipation: High-speed circuits tend to generate more heat. Without proper routing and thermal management, excessive heat can damage components or degrade performance.

Best Practices for High-Speed PCB Routing

To overcome these challenges, here are some essential practices for routing high-speed PCBs:

- Use Short and Direct Traces

- Shorter traces help to minimize signal delays and reflections. The longer the trace, the greater the chances of signal degradation. For high-speed designs, keep traces as short and direct as possible to avoid unwanted signal distortion.

- Impedance Control

- Maintaining consistent trace impedance is vital in high-speed designs to avoid reflections and ensure signal integrity. To achieve this, it’s important to control the width of traces and the distance between them and the ground plane. This can be done by using impedance calculators or referencing PCB design guidelines.

- Minimize Crosstalk with Proper Spacing

- Crosstalk occurs when signals from one trace interfere with adjacent traces, which can lead to data corruption. Proper trace spacing helps to reduce crosstalk. A general rule of thumb is to keep the space between traces at least three times the width of the trace.

- Differential Pair Routing

- For signals like clock lines or data buses, using differential pair routing is highly effective. Differential pairs carry the same signal with opposite polarity, which helps in minimizing noise and improving signal integrity. When routing differential pairs, ensure that both traces are of equal length and that they run parallel to each other to maintain signal balance.

- Use Ground Planes

- Ground planes are crucial in high-speed designs as they provide a return path for signals, help reduce EMI, and improve overall signal integrity. It’s recommended to use solid, unbroken ground planes directly beneath signal layers and to keep return paths short.

- Avoid 90-Degree Turns

- 90-degree turns in high-speed PCB routing can cause signal reflection and impedance changes, which negatively affect signal integrity. Instead of using sharp corners, opt for 45-degree bends or smooth curves in your trace routing to minimize disruptions.

- Layer Stack-Up for Signal Isolation

- When designing a multi-layer PCB, carefully planning the layer stack-up can greatly enhance signal performance. Place high-speed signal layers between ground and power planes to reduce EMI and provide better signal shielding.

- Match Trace Lengths

- In high-speed designs, ensuring that signals arrive at their destination simultaneously is critical. For differential pairs and clock lines, ensure length matching of traces to minimize timing skew. Use serpentine routing if necessary to match the length of critical signal traces.

- Decoupling Capacitors for Power Integrity

- To maintain power integrity, place decoupling capacitors as close as possible to power pins to filter out noise and prevent power-related signal disturbances.

- Thermal Management

- Effective thermal management is essential for high-speed designs. Use wider traces for power distribution and incorporate thermal vias to help dissipate heat generated by high-speed components.

Tools and Techniques for High-Speed PCB Routing

Modern PCB design software includes various tools that can assist in high-speed routing. Some of the features to look for include:

- Signal Integrity Simulation: This tool allows you to simulate how signals will behave at high speeds, helping to predict potential issues before the design reaches production.

- Auto-Routing with Impedance Control: Some design tools offer auto-routing options that consider trace impedance and other factors essential for high-speed routing.

- Crosstalk Analysis: This feature helps identify areas where signals are too close and at risk of causing interference.

Conclusion

High-speed PCB routing requires careful attention to detail and an understanding of the complex dynamics involved in signal transmission at higher frequencies. By following these best practices—shorter traces, impedance control, differential pair routing, and proper thermal management—you can ensure that your PCB design performs optimally, minimizing noise and maintaining signal integrity. Whether you’re working on a multi-layer PCB or a dense design, these strategies will help you tackle the challenges of high-speed PCB routing with confidence.

Also Read : fpga architecture in vlsi

To know more about VLSI Course , SuccessBridge VLSI training institute. You can begin your VLSI career by enrolling in the placement-assisted live courses available at SuccessBridge We offer various VLSI online courses. We offer VLSI Physical Design course, Design Verification course, DFT Training , Chip design course many more. Explore VLSI Courses From The Leaders In VLSI Training